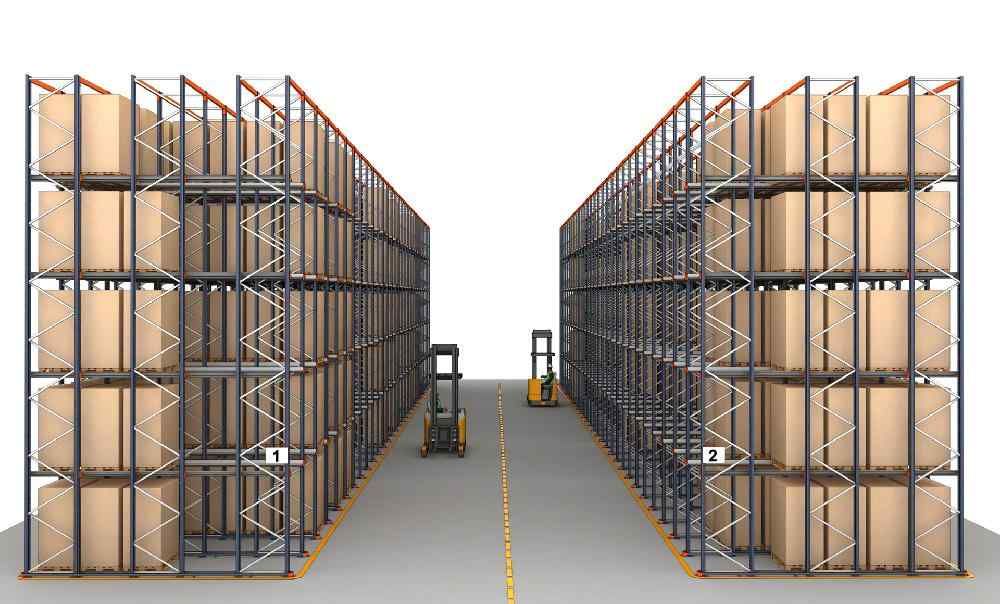

Drive-In Racking

Pallet Drive-in Racking, Cost-Effective, High Density Storage Solutions.

Drive In Racking

Pallet Drive-in Racking is used in warehouses and distribution facilities when pallets and items require a cost-effective, high-density storage solution. The Drive-in pallet rack is a first in, last out (FILO) storage system due to its architecture. To make the most of warehouse space, drive-in racking is best employed with a huge amount of similar products that aren’t time-sensitive. The drive-in rack keeps warehouse access aisles to a minimum, allowing users to achieve double or more storage capacity.

Drive-in pallet rack systems can

accommodate anything from two to ten pallets per pallet location. Drive Pallet rack systems hold pallets that are driven into the rack system and loaded onto horizontal rails by forklift operators. When it’s time to

transport the pallets, drivers remove them from the same entrance point where they were loaded. Drive-in rack systems are usually installed against a wall or have one end of the system closed.

How It Works

Drive-Thru pallet storage systems work on the same principle, but they’re set up in an open space so forklifts can drive right past them.

- Maximum pallet storage

- Virtually infinite storage depth

- Fewer aisles, resulting in better space utilization

- Cant-leg or set-back leg designs can assist protect against forklift damage

- Custom-designed for your pallets and forklifts

- Cost-effective storage strategy

- Can be combined with a pushback pallet rack to produce a combined system

Interested in our services?

We’re here to help!

Reach out to Storequip now and let us transform your storage space with our expert racking installation services.